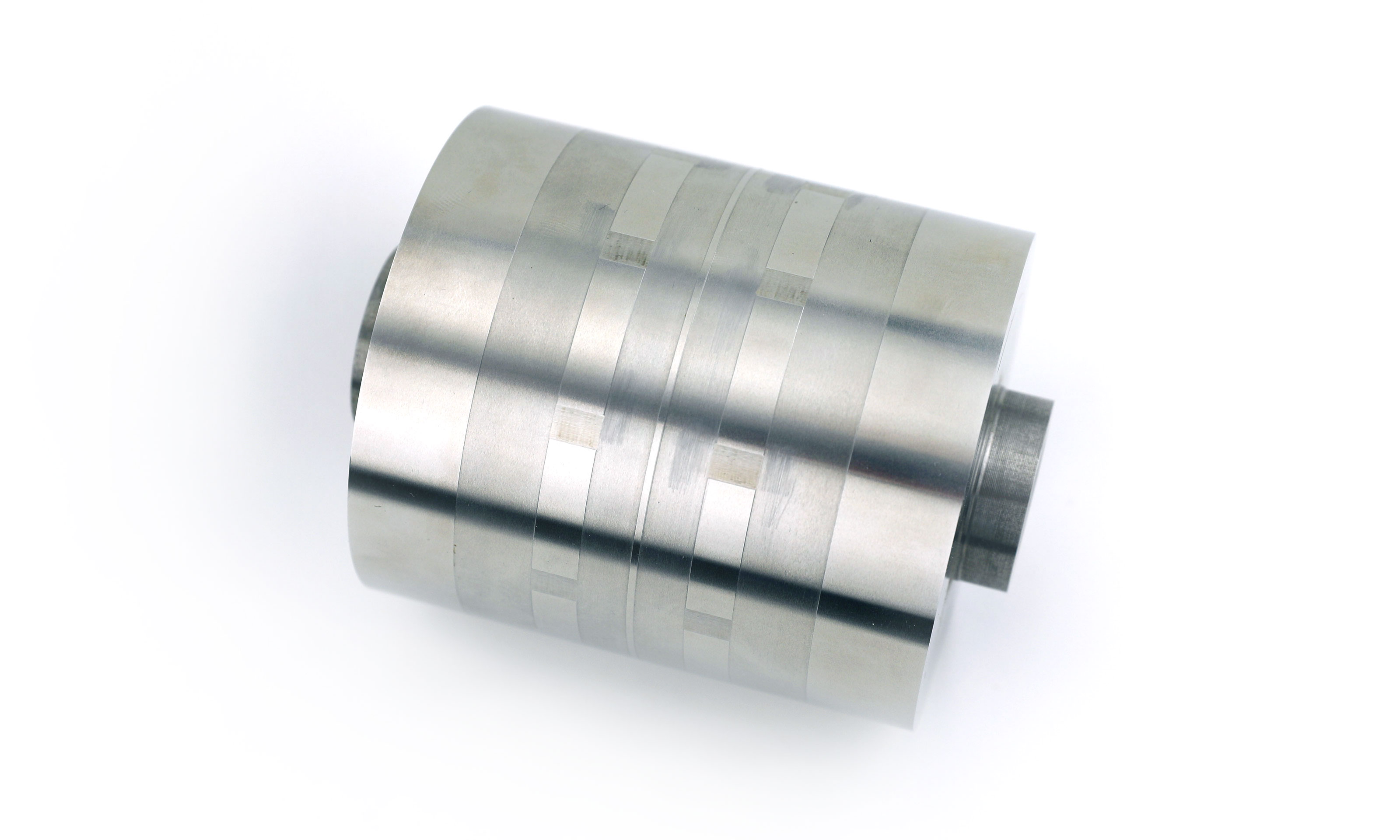

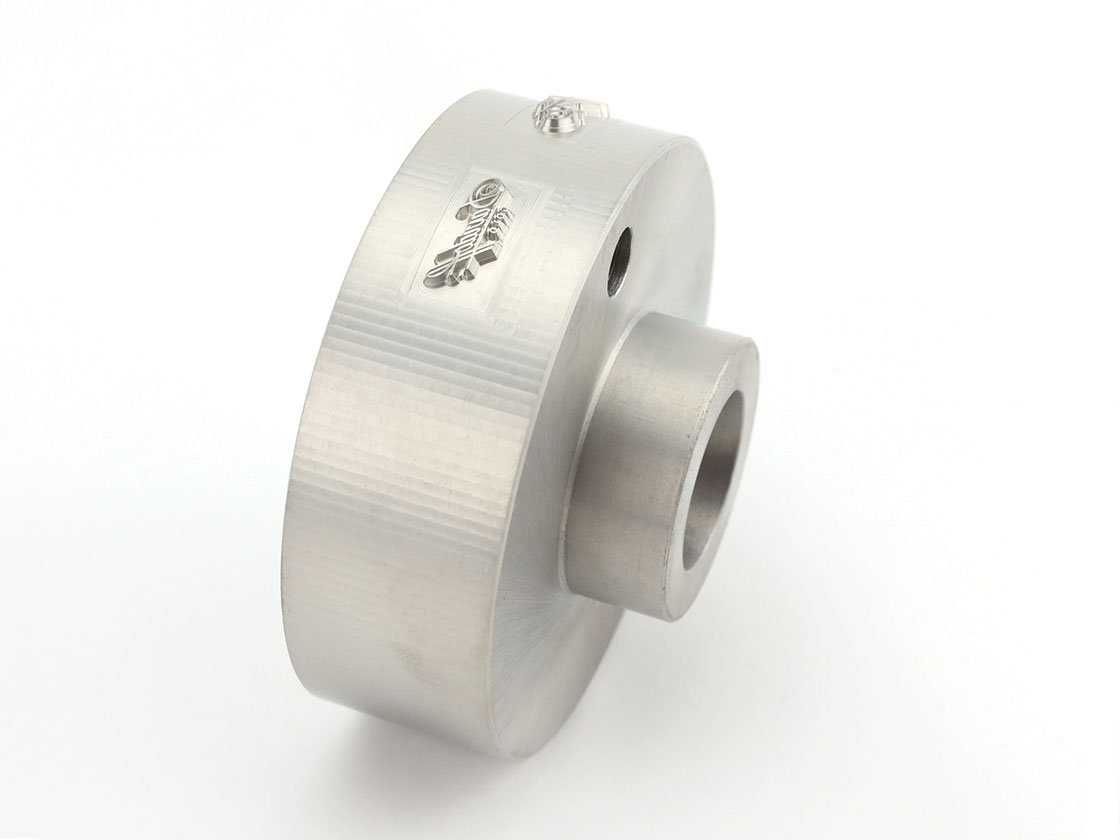

Glue rollers

Rotorprom manufactures glue rollers suitable for any type of filter adding machines: MAX, PA, GD, SASIB, ITM etc.

Description

The present group of parts is used to transfer the glue mass with specific critical characteristics to filter paper (tip) ensuring the perfect adherence of the lit end of a cigarette to the filter. To determine the exact content of nicotine and tar per cigarette the glue rollers are provided with perforating windows to create ventilating areas on the inside of a tip. While manufacturing these parts, we carried out researches and developments aimed at the following:

- improving the design of rollers,

- extending their lifetime,

- improving the performance of transferring the glue to the tip,

- reducing the flow of the glue up to 30% due to strip-sectoral topography.

We also produce glue rollers for packaging equipment.

Advantages

The results of tests conducted at enterprises showed that corrosion-resistant steel along with the pertinent conditions of heat treatment allows for extending the lifetime of rollers from 4 to 6 months to 9 to 14 months, in case of three-shift operation. Upon development of our own manufacturing technology we managed to reduce the runout tolerance of the work area from 0.01 mm to 0.005 mm. This changed parameter led to reducing the downward pressure between main and transmitting rollers from 1.7 to 1.3 MPa.

The manufacturing accuracy of perforating windows and the work surface finish allowed us to significantly reduce the chemisorption bonds between the glue and the metal. Due to the abovementioned characteristics the flow of the glue was reduced to 10 to 12% during first 3 working months compared to similar parts of other manufacturers.

Thank you!

We will contact you as soon as possible.

Contact us

We will be glad to discuss your project with you.